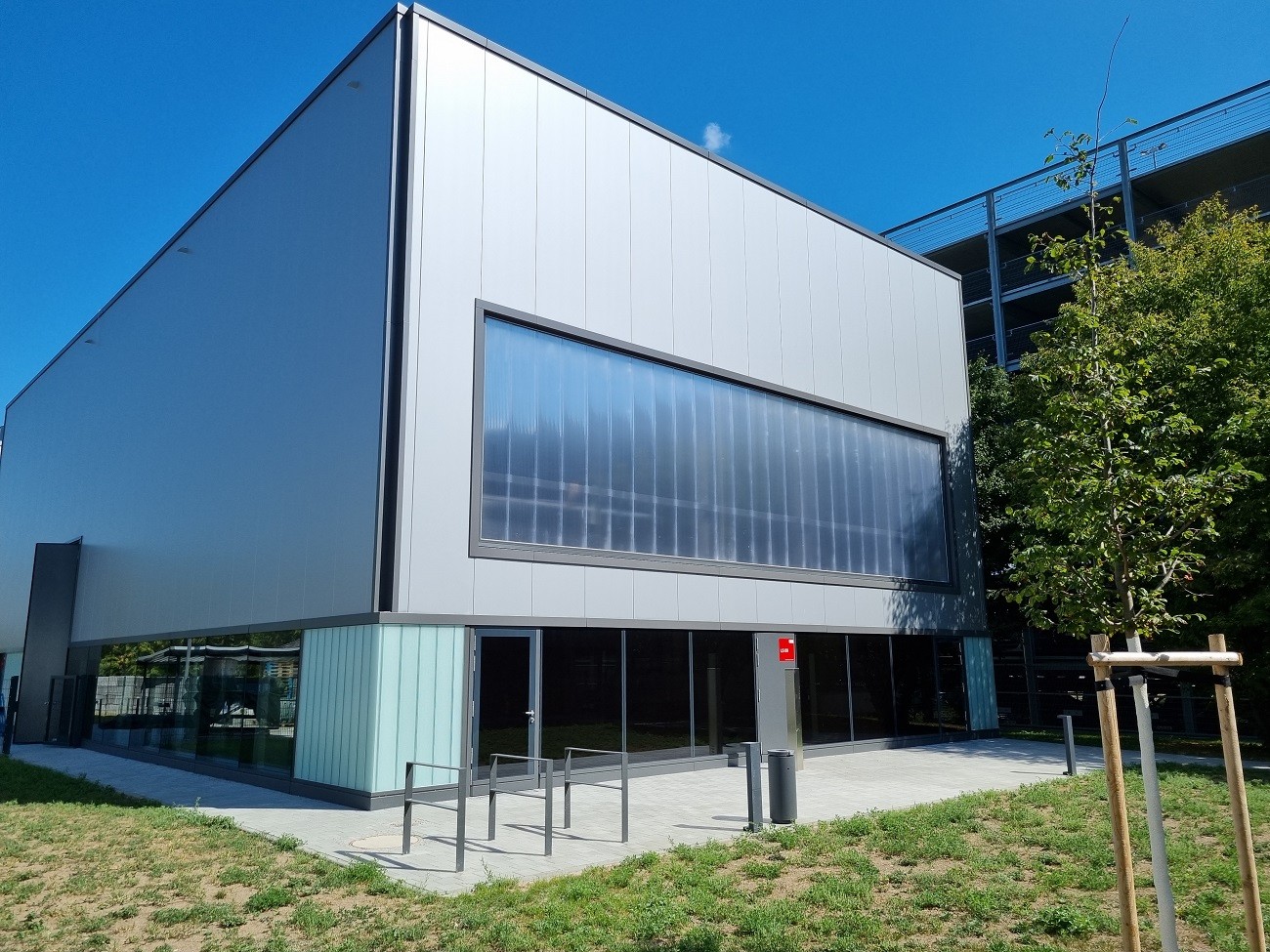

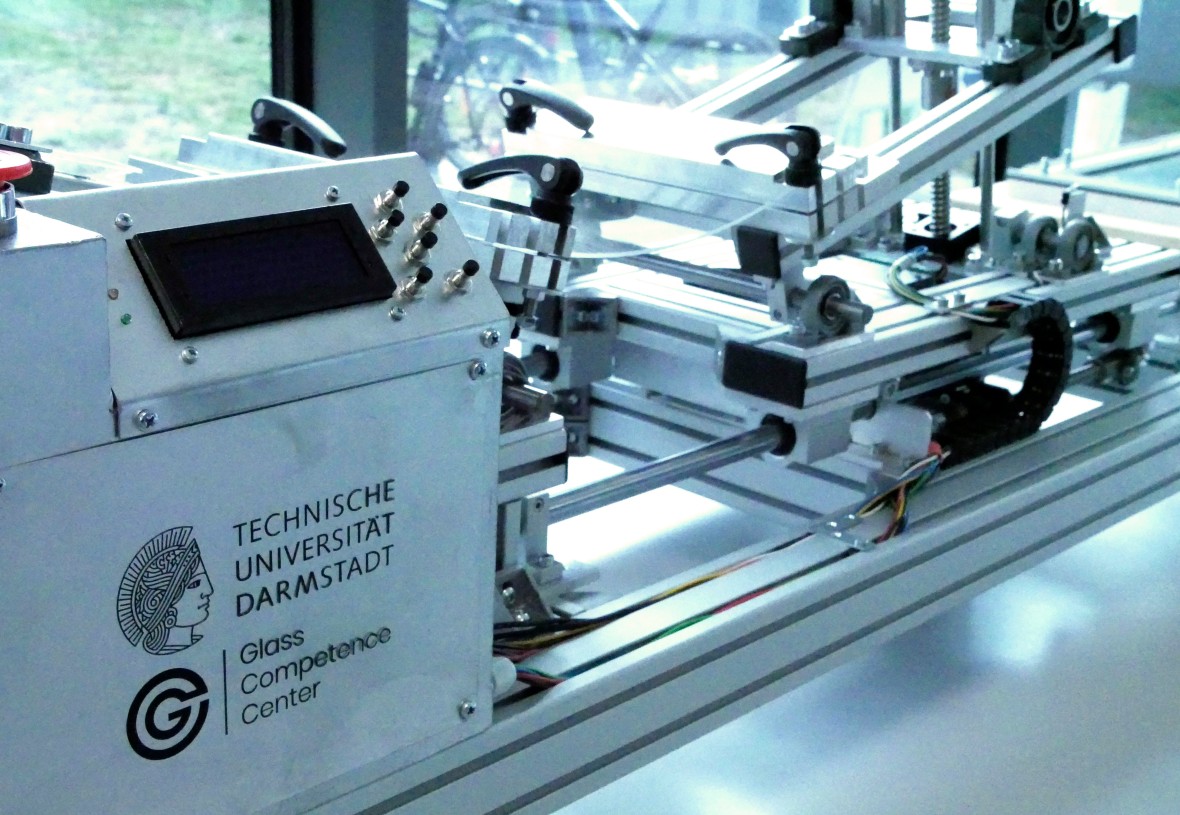

The rare combination of transparency, strength and durability is what makes glass so fascinating as a building material and extremely attractive for various applications, such as in facade and automotive construction. However, the potential of glass, a comparatively old and recyclable material, has not yet been exhausted. With new technologies, such as additive manufacturing and artificial intelligence, as well as continuous research, the performance and application range of glass can be further expanded. The newly founded Glass Competence Center (GCC) at TU Darmstadt is making a significant contribution to this in the university environment. The GCC combines the competences of the Institute of Institute of Structural Mechanics and Design (ISM+D) and the Materials Testing Institute (MPA-IfW) in the field of structural glass engineering and façade construction. In the newly created research building, all essential processes of flat glass processing can be realized. Specifically, flat glass can be cut, ground, drilled, washed and laminated into laminated safety glass by the processing machines. Other machines, such as a thermal tempering line and a glass melting furnace, are in the planning stage. In addition to the glass processing machines, the GCC has a bonding lab, a melting lab and an optical lab for analyzing glass products. Other equipment highlights include the self-developed glass 3D printer for printing on flat glass and a facade test stand (dimensions 12 m x 3.6 m). These facilities in combination with the excellent investigation possibilities enable us at the GCC to combine theory and experiment in research, to develop sustainable innovations together with our partners, to offer our students an ideal learning environment in teaching and research and to strengthen the exchange of knowledge between users, authorities, industry, students and researchers.

More info here