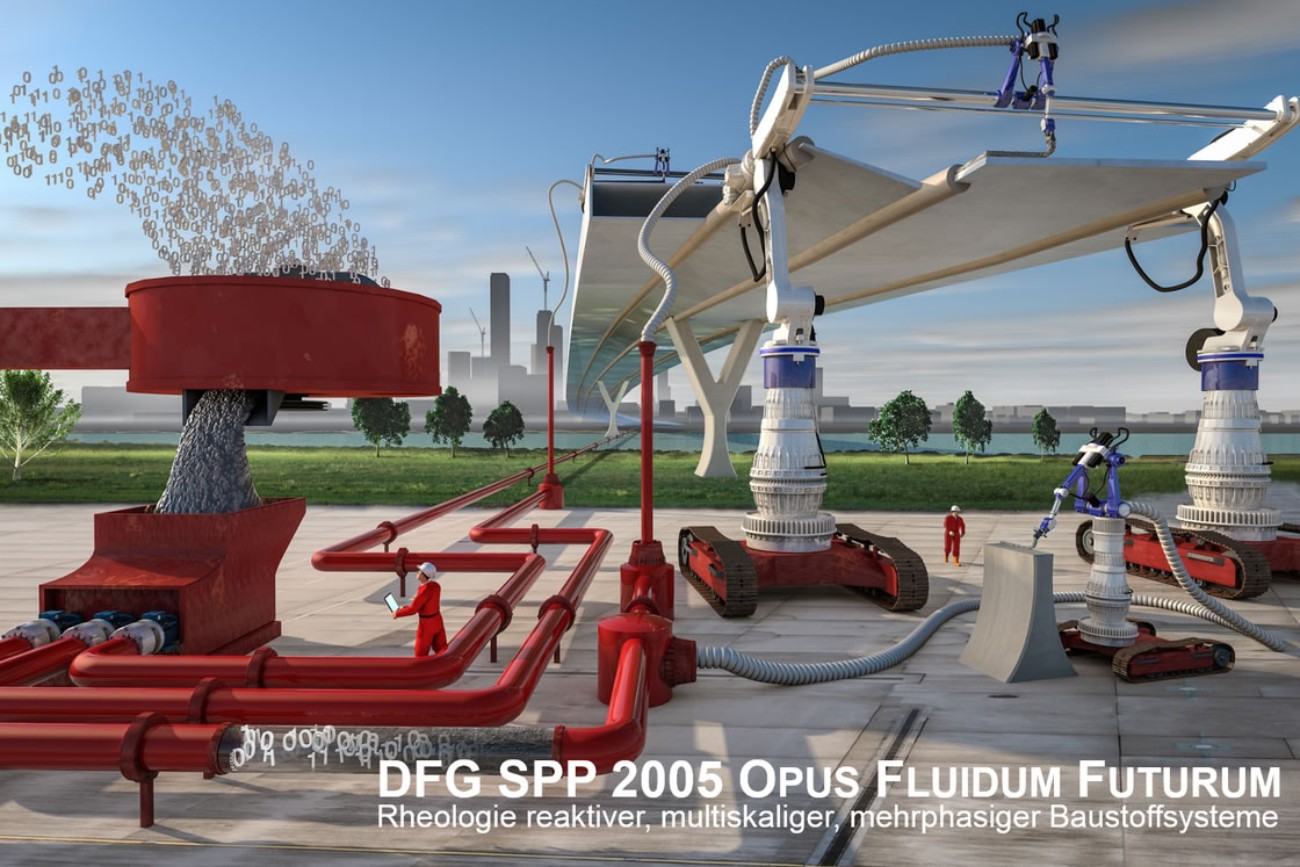

| Acronym | SPP 2005 |

| Project name | Form filling ability of fresh concrete: A time and hydration dependent approach |

| Coordinator | TU Darmstadt, Institute of Construction and Building Materials |

| Project partner |

|

| Duration | since 2017 |

| Grantor | German Research Foundation (DFG) |

| Project content |

The project aims to analyse the formwork filling ability of fresh cementitious materials (mortar, concrete) and provide a numerical simulation of formwork filling ability based on a rheological model. The model takes changes in the rheological properties (thixotropy) with time and their dependence on shear rate due to hydration processes into account. The rheological parameters are derived from the physical properties of the initial materials as well as mix composition.The rheological parameters yield stress, viscosity and thixotropy are varied with respect to a reference mix specified in the SPP central project. By suitable adjustment of the mix composition, only one rheological parameter at a time is varied. This approach enables quantification of the effect of material characteristics on the rheological parameters which can then implemented in a rheological model.In order to verify the rheological model with regard to formwork filling ability, the rheological measurements are accompanied by investigations of the formwork filling ability of mortar and concrete in box and L-shaped model formworks. The rheological model is implemented in computation fluid dynamics CFD in order to numerically calculate the flow and formwork filling ability of the material in any desired formwork. This method is developed further by calculating the rheological input parameters with the help of an aging shell particle interaction model (micro DEM). The micro DEM model simulates the processes occurring during the dormant phase of cement hydration at the particle level. These processes are related to the experimentally determined, time-dependent rheological behaviour of the cementitious systems, in particular the formation of thixotropic structures. The results are then used as input for the meso and up-scaled CFD modelling. Thus the formation of thixotropic structures is included in the CFD simulation and related to the processes and interactions at the particle level. The CFD simulation of formwork filling ability is therefore able to take the effects of mix composition, material properties and hydration processes at the particle level into account. The ability of this modelling approach to predict formwork filling ability from the mix composition alone is demonstrated by designing a test concrete composition which fulfils the requirements for optimum formwork filling. The formwork filling ability of the concrete is computed using the micro DEM model with the upscaled CFD simulation and compared with the corresponding test result. |

|

Projecthomepage |

|

Department of Civil and Environmental Engineering

Research project SPP 2005

Research project SPP 2005